Custom MEMS development and production

LioniX International specializes in custom MEMS development and manufacturing. Our philosophy is that there are ‘no two MEMS alike’. We therefore offer optimized methodologies for custom MEMS design and custom MEMS process development and engineering and MEMS fabrication processes to precisely meet your specifications without compromising on functionality.

During our history we have served hundreds of customers and put numerous MEMS applications into production successfully. During these efforts we accumulated an incredible amount of MEMS processing knowledge which we apply to new customers’ projects every day.

For our MEMS manufacturing we use ‘state-of-the-art’ equipment allowing flexible processing routes without jeopardizing process stability and cross contamination.

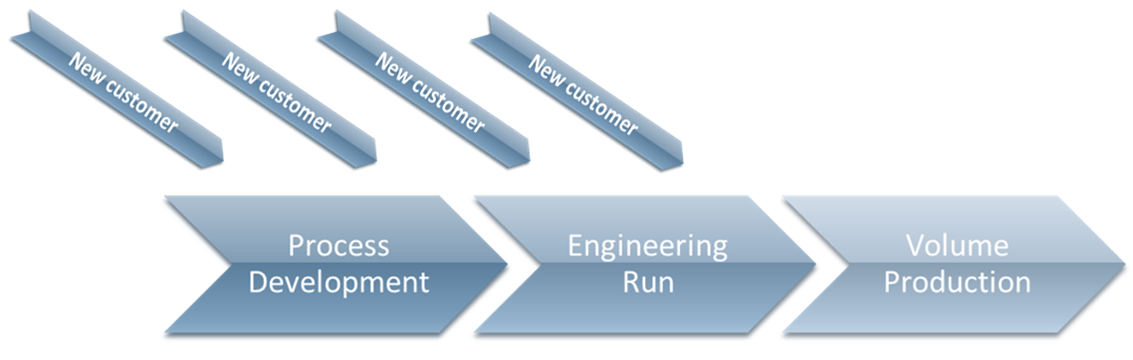

Project phases for MEMS development, engineering and manufacturing

As a MEMS partner we work with you to co-develop your MEMS product. During the development you will always be in control and involved in important decisions. You can stop the development at any time.

Depending on the maturity of your ideas and work done, we may start a project with you at any one of the following phases:

Feasibility

A full development project may start with a feasibility study. In this phase we will investigate and report on whether a MEMS product meeting your specifications can be developed and manufactured. We will work with you to explore the risks and define white spots in the process in short loops. Manufacturing costs per chip and non-recurring costs will be estimated.

Custom MEMS process development

In the MEMS process development phase, we isolate and execute parts of the manufacturing process outside the main project. These process short loops will therefore not put whole batches at risk, and minimize development costs. Depending on the outcome, we may advise on changes in the manufacturing process.

MEMS Prototyping

Once the MEMS process is in place, we can start a MEMS prototype run. This phase is used to further refine parameters, with flexible specifications and we will expect some variation in outcome Yielded chips may be used for proof of concept or for further fund raising. The prototypes can also be used to verify MEMS design models, start packaging work, address system integration, and test device performance.

MEMS Engineering run

In the an engineering run the focus is on yield improvement, test optimization, cost optimization and ramp up of production volumes. We work to ensure that specifications converge to their final values.

MEMS Production

In the MEMS production phase, the design and process are frozen, and specifications are fixed. We track and document every step of the process, guaranteeing full wafer and chip history. We can deliver diced wafers on foil, or package your chips in trays. If you require us to, we can fully test all all of your chip. The risks of non-yielding wafers/chips are on our side.

MEMS manufacturing services and outsourcing

As a MEMS partner we also offer stand-alone MEMS manufacturing services as part of your existing manufacturing flow and provide full outsourcing for some or all of your MEMS development and production requirements.