MEMS Technology

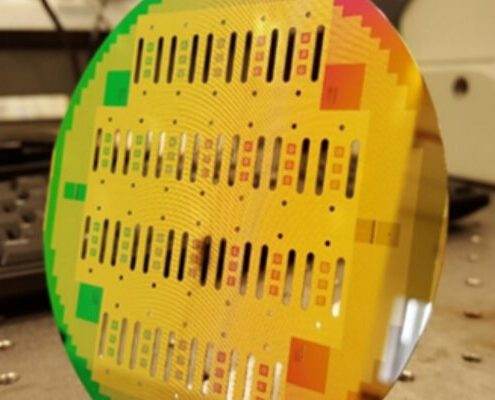

With over 20 years of experience in microsystems fabrication using MEMS technologies, we have developed a valuable array of technologies designed to realize your MEMS device. Deep reactive ion etching and and wafer bonding are key amongst these vital enabling technologies.

Through continual development in our state of the art cleanroom we have refined existing technologies and continue to develop new custom capabilities in partnership with our customers.

You will find an overview of all of our most important MEMS technologies and building blocks below.