About Project POLYNICES:

Project POLYNICES aims to further develop integration between photonic and electronic integrated chips with the development of a new Electro-Optic Printed Circuit Board (EOPCB). Current methods for the integration of photonic and electronic chips involve various assembly and packaging processes which are almost entirely separate from other fabrication processes. Assembly and packaging accounts for the majority of avoidable production costs. By developing a versatile mediation solution, POLYNICES aims to combine existing integration technologies into a scalable, multi-functional, and holistic assembly and packaging approach.

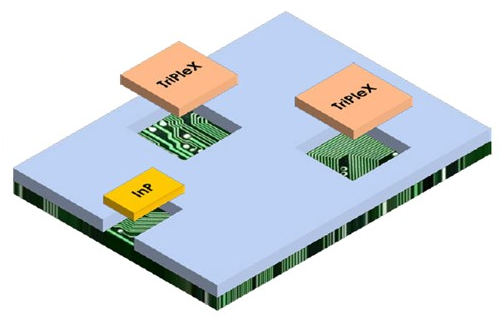

The major component technologies of POLYNICES are Fraunhofer HHI’s PolyBoard material and LioniX International’s TriPleX® waveguide platform. A PCB coated with the PolyBoard material will play the role of a EOPCB motherboard, with slots etched into the coating into which TriPleX® chiplets can be easily inserted and electronically connected. Other components, such as indium phosphide photodiodes and amplifiers and photoconductive antenna will be integrated on the EOPCB motherboard in the same manner. The TriPleX® chiplets will host circuits based on existing designs and featuring customized alignment stops for ultra-low loss compatibility with the motherboard. Various chip- and wafer-scale integration methods will be investigated, including flip-chipping, passive alignment, and laser soldering.

Two final demonstrator modules will be developed and produced through POLYNICES: an optoelectronic frequency-modulated continuous wave beamformer with > 2 THz bandwidth, and a quantum information processor with a record-setting 24×24 matrix. Ancillary technologies for the demonstrator modules to be optimized for the project include stress-optic actuators and THz antenna elements. The beamformer will be evaluated through its use in quality control testing of plastic pipes, focusing on resolution, penetration depth, and defect identification. The quantum information processor will be evaluated on its ability to demonstrate Boson sampling as well as the operation of quantum logic gates for the manipulation of high-dimensional quantum states.

Artist’s impression of the EOPCB motherboard with slots for TriPleX® chiplets and an indium phosphide section. The PolyBoard material is in light blue.

The Role of LioniX International:

Using our existing devices as a starting point, we will optimize our circuit designs and production methods to produce motherboard-compatible chiplets. These chiplets will act as photonic building blocks for the complete module.

Our external cavity laser at 1550 nm will be redesigned for the beamformer, along with a new 780 nm laser design with high power output and ultra-narrow linewidth for the quantum processor. Both 1550 and 780 nm lasers will feature a new chip-on-carrier design, where the gain chip is placed inside a pocket in the TriPleX® chiplet. This will enable easy integration of the TriPleX® chips into the EOPCB motherboard.

For the beamformer unit, stress-optic PZT actuators will be crucial for fast and energy efficient phase shifting. These actuators have been deployed in project 5G-PHOS and will be further optimized for use in POLYNICES, targeting increased speed, decreased electrode length, and lower power consumption.

For the photonic quantum processor, new 8×8 Clements and Blass matrices will be designed and fabricated. We have considerable experience with quantum processors through our work for QuiX Quantum (a member of the project’s symposium). Our Blass matrices were also deployed in the SPACEBEAM project. A new squeezed light generator will also be developed, featuring tried-and-true TriPleX® building blocks such as cascaded Mach-Zehnder interferometers for light splitting and arrayed micro-ring resonators for light squeezing. The generator will also be equipped with integrated filters, operated using PZT actuators which will also be used in the splitting and squeezing stages.

LioniX International will also contribute to the development of the packaging methods of the TriPleX® chiplets, the testing methodologies, and the overall production process flow.

Further Information:

🌐 Visit the project’s website for more information about its goals, results, and consortium members.

🌐 Visit the project’s CORDIS tracker.

🌐 Watch the project’s official video!

🌐 Read Franhofer HHI’s press release about POLYNICES.

🌐 Read PHIX Photonic Assembly’s press release about POLYNICES.

🌐 Read QuiX Quantum’s press release about POLYNICES.

🌐 Read about Project FLEXIT, an interlocking assembly approach for indium phosphide and TriPleX® integration.