BIOMED : Lab-on-chip, organ-on-chip, and cell production technology

Lab-on-chip (LoC), organ-on-chip (OoC), and cell production technology: The Netherlands is rich in knowledge awaiting INTEGRATION. The NXTGEN Hightech program presents a clear strategy for merging this knowledge and translating it into tangible products and innovative applications.

In recent years, The Netherlands has emerged as a hub of high-tech innovation, with a significant academic expertise in domains such as Lab-on-Chip, Organ-on-Chip, artificial organs, and cell production technology. Despite this wealth of knowledge, challenges arise in the translation of academic expertise into tangible products and real-world applications.

Taking a step forward toward bridging the gap between theoretical wisdom and practical implementation, LioniX has taken a proactive role alongside various partners within project Biomed, a NXTGEN Hightech initiative. This collaborative effort seeks to combine expertise related to chip production, cell production, and bioactive materials to address developments in five key directions (of which LioniX contributes to the first four):

- One-stop-shop

- Lab-on-a-chip

- Organ-on-a-chip

- Cell Production Technology

- Artificial Organs

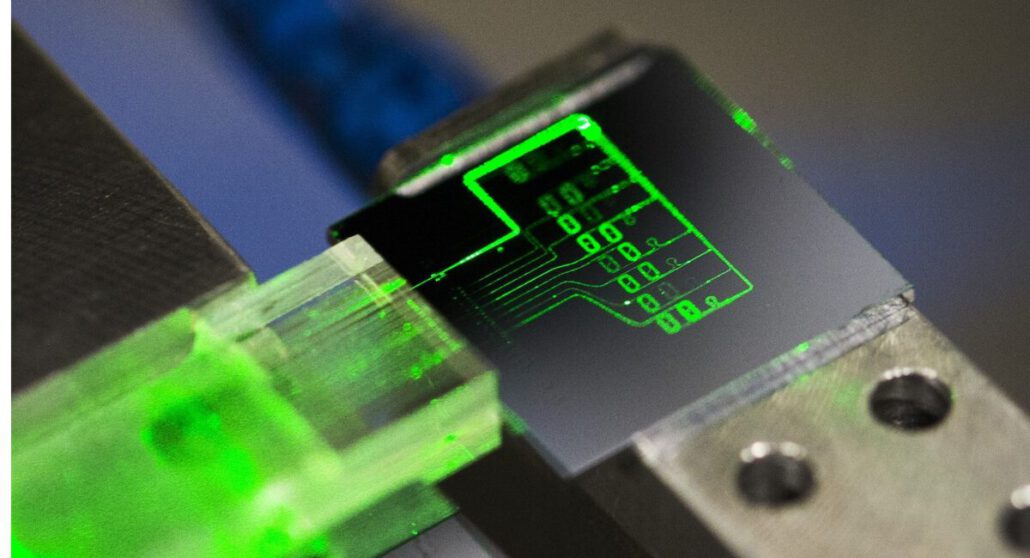

Figure 1: Integrated photonics are enabling biosensing chips that offer fast, affordable, and highly sensitive analytical tools for point-of-care applications.

Biomed 01: One Stop Shop

The Netherlands possesses high academic expertise in Lab-on-Chip, Organ-on-Chip, artificial organs, and cell production technology. However, this knowledge is not effectively translated into products due to the lack of a coordinated production chain. Despite having the necessary players in the semiconductor, medical devices, and biotech sectors, their equipment and processes are not yet compatible. Biomed’s One Stop Shop subproject aims to establish a multidisciplinary partnership to bridge the ‘Valley of Death’ gap between prototype development and market-ready biomedical products.

The project seeks to establish a comprehensive Biomedical Production Technology ecosystem, where shared knowledge, equipment and processes are brought together, referred to as the One-Stop-Shop. This online platform will allow end-users to have access to multidisciplinary knowledge and technology that focuses on three key elements: manufacturable biomedical building blocks, development of production machines, and shared production processes.

The general project (‘One-Stop-Shop’) will consist of setting up and organizing the operation of the production chain:

- Expanding and organizing the ecosystem (in collaboration with High Tech NL);

- Developing standards for (international) standardization (in partnership with NEN);

- Establishing processes and equipment for functional qualification (in collaboration with hDMT, RIVM, CBG-MEB);

- Creating a (virtual) pilot line for product-ready integration and assembly for scale-up.

The broader project involves expanding and organizing the ecosystem, developing international standards, establishing processes for functional qualification, and creating demonstrators and a virtual pilot line for product-ready integration and assembly. Through this program, The Netherlands aims to convert its knowledge leadership into a global production powerhouse. By fostering collaboration, setting shared goals, and generating direct earning capacity, The Netherlands is set to lead in the development of patents and processes for the next generation of biomedical applications worldwide. The program seeks to make The Netherlands a global player in high-tech production technologies within the next 10 to 20 years.

Biomed 02: Lab on Chip

The second subproject under Biomed framework concerns the development of an infrastructure for equipment and processes for the volume production chain of Lab-on-Chip. This enables the miniaturization of complete, large scale labs, onto a microscopically small chip and is able to combine different components based on multi-analyte, point-of-care diagnostics systems, including connected disposables, i.e. cartridges, test-specific sensor chips and microfluidics for three biochip platforms with demonstration applications.

The challenge lies in integrating electronic, photonic, microfluidic, and biotechnological functionalities. The process steps required for the manufacturing of the biochips, gluing, assembling, and packaging are currently incompatible with existing Semicon processes and equipment. Maintaining the state of the art is based on many manual actions due to the current relatively low production volumes, resulting in diagnostic test costs being too high for most potential applications. To solve this problem, the project aims to develop new equipment with a high degree of automation and come up with innovative processes.

The project’ goal is to achieve affordable production of high-tech LoC systems through scalable processes, similar to the semiconductor ecosystem. Key areas targeted by the projects include engineering and manufacturing, photonics and light, life sciences, and nano-/chemical technologies.

Two platforms are being co-developed by LioniX as part of the project:

Integrated Photonics (IPx) Biochip: This platform utilizes a proprietary refractive index (RI)-sensitive, asymmetric Mach-Zehnder Interferometer (aMZI), under development in several ongoing projects (private investment, PhotonDelta, EU). LioniX International provides a world-record ultra-sensitive label-free sensor chip based on its TriPleX® (silicon nitride) platform, and Surfix Diagnostics develops the diagnostics platform, optimized with their material-specific biofunctionalization technique. The demo applications include early cancer detection (Qurin Diagnostics) and a test for the veterinary sector (Health Service for Animals, GD). Alternative RI sensor designs are being developed in a demonstrator for screening leads in drug development (Delta Diagnostics).

CRISPR-Cas Technology Platform: This platform incorporates CRISPR-Cas technology developed by Wageningen University & Research (WUR) and Scope Diagnostics. It detects specific DNA and RNA sequences using the microfluidics implementation of a Laser-Induced-Fluorescence (LIF) bioassay (Micronit), with a unique and highly sensitive IPx-based biochip from LioniX. Demo applications include tests for pathogens like the COVID virus, other infectious diseases (Scope, NYtor), and long-term early cancer detection (UT and VUmc).

These platforms allow measuring multiple parameters possible in one sample and can be used for a whole range of analytes such as DNA and proteins (antibodies), metabolites, cells, pathogens/bacteria, pesticides, antibiotics, toxic molecules, etc. Other non-photonic chip-based principles will also benefit from this LoC production infrastructure because the provided diagnostic system concept is generically applicable.

Biomed 03: Organ on Chip

Organ-on-Chip is a revolutionary method to scale down organ systems down onto a small chip, making it possible to study the physiology on a sub-scale and severely reducing the need for animal testing in drug discovery.

This third subproject aims to bridge the production-commercialization gap referred to as the ‘Valley of Death’ by collaboratively establishing a multidisciplinary production chain involving chip developers, machine builders, process technologists, and biologists.

The project focuses on creating three demonstrators, each with varying levels of complexity and designed for interchangeability:

Demonstrator 1 is a system involves 96 parallelized cardiac muscle tissues derived from stem cells. It includes automatic detection of force and is later expanded with a perfusion system.

Demonstrator 2 is a perfusion system that serves to drive a modular OoC system based on the Translational OoC Platform. End users can use a “plug & play” approach to bring together tissue chips, commercial sensors, and fluidic components, and perform OoC tailor-made applications.

Demonstrator 3 involves integrating similar components into a standalone, wireless, ‘smart’ OoC system with the size of a standard cell culture plate. The modular character of this system is maintained, and agreements are made about interfacing, control, and reading methods. The goal is to create a standardized approach, making it easy to efficiently produce large-scale OoC systems with high quality after the project.

The main focus of LioniX within this project is to bring a novel detection possibility to the OoC world: three-dimensional imaging using Optical Coherence Tomography (OCT).

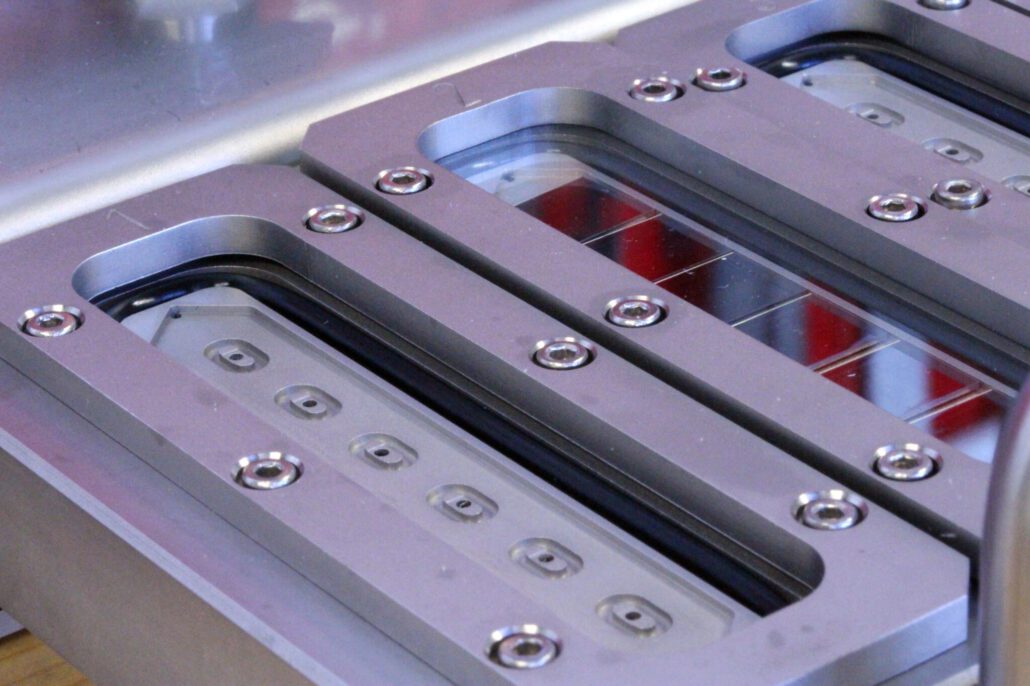

Figure 2: A fluidic system

OCT is the optical analogue to ultrasound imaging and brings the advantages of optics to this domain, by enabling micrometer resolution on a millimeter depth scale. LioniX will work on integrating this technique on a chip scale to bring this large, costly and hard to integrate technique towards an integrated solution.

The overall objective is to establish a production chain that facilitates the development of practical Organ-on-Chip applications. By collaborating across disciplines and creating modular, interchangeable components, the project aims to enable the efficient production of large-scale, high-quality Organ-on-Chip systems in the future.

Biomed 05: Cell Production Technology

This subproject focuses on advancing cell culture technology, recognizing its important role in addressing future health challenges. Specifically, the project aims to develop cutting-edge equipment for cell culture applications, with a focus on improving the cultivation of high-quality cells for various purposes. Examples include cell-based diagnostic assays (Lab-on-Chip), mini-tissues for drug screening (such as Organ-on-a-Chip), as well as vaccine and viral vector production.

The project’s primary goal is to create the next generation of high-tech equipment by incorporating innovative sensor technology and integrating it through microfluidics. This integration enables precise control over the cell culture process, ultimately leading to the production of high-quality cell and cell-derived products.

High quality cell production lines require gathering real-time data from the production plants, and therefore sensors are an integral key to this technology. LioniX is bringing its established biosensor platform which has strong links to the LoC biomed domain. Going beyond point-of-care applications, continuous measurements are required where the sensor is no longer disposable but constantly reusable. A novel technique by integrating enzymes on the biosensor will enable the sensors for this high demanding application.

Figure 3: An Optofluidic setup

Furthermore, the project contributes to the overarching ambitions of NXTGEN Hightech, addressing a significant societal challenge related to rising healthcare costs. The increasing demand for healthcare necessitates controlling costs, and the project recognizes the potential of innovative therapies, advanced diagnostic tools, and efficient drug screening in meeting this challenge. However, the high costs associated with qualified personnel, production facilities, and the risk of production errors are barriers to cost-effectiveness.

The project addresses these challenges by focusing on the automation of cell culture processes, aiming to standardize product quality and reduce personnel costs. This requires the integration of new technologies, particularly the latest sensor technologies, to monitor and control the production process.

FURTHER INFORMATION:

🌐 Visit the project’s website for a full rundown of its aims and partners.

🌐 Read more about TriPleX® technology and photonic biosensors development at LioniX.

🌐 Subscribe to our newsletter!

Project empowered by NXTGEN hightech.