Inlite (Inspiring Novel Light-Integrated Technology & Equipment)

About Project Inlite

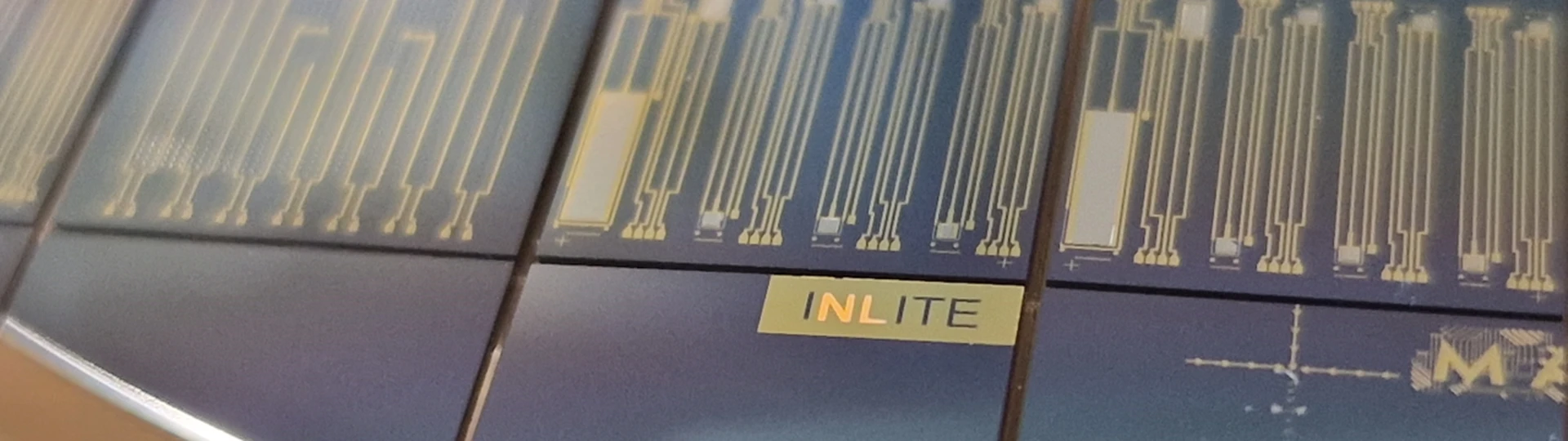

In this project, efforts are focused on developing production equipment for integrated photonics to enable mass production of these components and devices. The project concentrates on standardizing both front-end and back-end production processes for manufacturing wafers with Photonic Integrated Circuits.

The goal of the project

The goal is to develop machines for various product families that utilize standard substrates such as SiN and InP. These developments are crucial for assembling the components and integrating various coupling methods. Additionally, the project seeks to advance new process developments in front-end techniques such as PLD and CVD.

The Role of LioniX International

LioniX leads efforts to develop and validate advanced PICs that are essential for testing and refining assembly processes. Our work focuses on establishing standardized test and assembly methods, addressing the industry’s lack of standardized protocols, and fostering greater efficiency and scalability in PIC manufacturing.

Completed Activities

LioniX International has already made significant strides in the Semicon 09 project, contributing a range of test structures and methodologies that advance assembly capabilities for PICs. Key activities completed so far include:

• Fabrication of initial test structures to evaluate flip-chip methodologies and soldering techniques.

• Distribution of test structures to project partners for collaborative testing and feedback.

• Implementation of feedback-driven refinements to enhance the functionality and complexity of the test structures, enabling more accurate assessments of assembly strategies.

Planned Activities

Looking forward, LioniX International has outlined several activities essential for further advancing PIC assembly and testing methodologies:

• Continue refining and expanding the range of test structures based on partner feedback.

• Develop additional packaging techniques, including etched recesses with solder for flip-chip integration of active components (e.g., laser diodes and detectors).

• Implement and standardize wafer-level testing approaches using grating couplers and flexible waveguides.

• Expand wafer-level packaging capabilities to enhance scalability and reliability in photonic assembly

FURTHER INFORMATION:

🌐 Visit the project’s website for all the details about the project and the partners involved